Is EV a new ERA or revolution in the mobility industry?

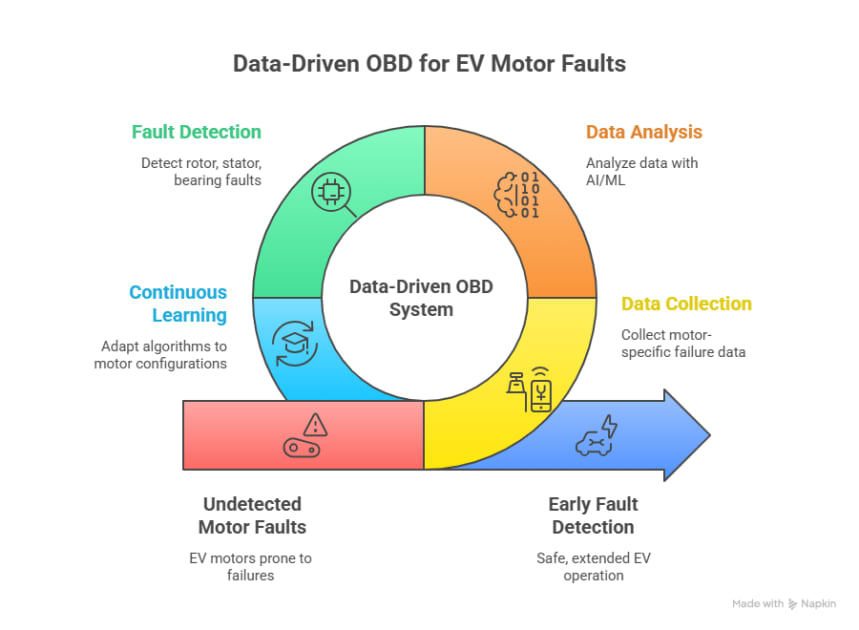

Data-driven Onboard Diagnostic (OBD) systems in EVs enable early detection of rotor, stator, and bearing faults using AI and analytics, enhancing safety, reliability, and cost efficiency while minimizing maintenance downtime and technician errors.

Conventional IC vehicle engines based on fossil fuels are being replaced by electric vehicles (EVs) as the primary form of mobility. However, EVs' safety concerns affect both end users and original equipment manufacturers (OEMs). Many reported failures are due to non-functional components or electric motor failures in EVs. Henceforth, an EV needs an inbuilt module to tackle such failures at its incipient stage. Fault diagnosis of these motors enables a safe operation for a more extended-run EV with a lower maintenance cost. Traditional solutions, such as Onboard Diagnostic (OBD) systems, can monitor and identify these failures at component levels, including electric motors, upon generating a diagnostic trouble code (DTC). However, the traditional OBD solution fails to do so for motor-specific failures in EVs, such as rotors, stators, and bearing faults. Therefore, generating streamlined fault codes at their incipient stages becomes challenging and takes longer than required. A data-driven OBD system can be an innovative solution that can collect and analyse a wide range of motor-specific failures by analysing modern data analytics, machine learning, and artificial intelligence. Henceforth, it makes it possible to monitor comprehensively and locate potential failures such as rotor, stator, and bearing problems early on. Furthermore, to overcome the problem of motor variability, the system may continuously learn from past data and modify its diagnostic algorithms to suit different motor configurations. Additionally, data-driven OBD solutions can offer more precise fault codes, ensure accurate fault detection and reduce technician misinterpretations.

The capability to detect faults in the rotor, stator, and bearing parts of electric motors in electric two-wheelers and electric four-wheelers is pivotal for guaranteeing the reliability and long lifespan of these vehicles. With the widespread growth of electric vehicles (EVs) around the world, the need for maintaining optimal operating efficiency while limiting downtime and maintenance expenses has never been so imperative. A fault diagnostic system has the potential to improve the performance of EVs considerably by detecting faults even before they result in major malfunctions. The system ensures that the vehicles become better in terms of overall safety, performance, and cost-effectiveness. Electric motors are the backbone of every electric vehicle, and any failure in these key components, such as the rotor, stator, or bearings, can have dramatic consequences. Among the most prevalent and significant failures within electric motors are rotor, stator, and bearing faults. Failure in the rotor can result in decreased motor efficiency or even full motor failure, whereas bearing faults mostly result in vibrations, heat development, and accelerated wear. Stator faults can result in power losses, overheating, and even full motor shutdowns.

By incorporating a sophisticated fault diagnosis system that is tailored to the rotor, stator, and bearings, early detection of such faults is made feasible. This system is capable of monitoring multiple parameters like temperature, vibration, electrical signals, and motor current. Through onboard sensors and diagnostic equipment, the system can make real-time checks of motor performance, detecting abnormalities in normal operating conditions that could be signs of developing faults. This initial detection ensures proper maintenance or repair before any serious failure occurs, and it lengthens the lifespan of the motor. This diagnostic system can potentially minimise maintenance costs significantly. Conventionally, motor faults are diagnosed through a manual inspection, which is time-consuming and costly. With an onboard fault diagnostic system, the vehicle can give direct feedback on the health of its electric motor components, warning the operator or the technician about problems. This lessens the requirement for high-cost diagnostic tools and enables technicians to direct their efforts toward rectifying the exact issue rather than making extensive, time-consuming tests. The onboard diagnostic system is also capable of delivering better fault detection accuracy. Legacy fault detection methods are typically hampered in their capacity to detect barely perceptible problems that would cause catastrophic motor failure. With the use of sophisticated algorithms and machine learning methods, the system can detect even slight deviations in motor performance. This translates into improved and more accurate fault detection, enhancing overall diagnosis and preventing unjustifiably expensive repairs.

The uses of such a diagnostic tool go far beyond single electric vehicles. In EV production, the incorporation of fault diagnosis systems can make the manufacturing process run more smoothly, with motors guaranteed to live up to the best standards of quality and reliability before they are available for sale. Moreover, development and research teams developing new motor technologies or electric vehicle models can also gain from applying these diagnostic tools during prototyping and testing, as they are able to detect points of failure early enough in the design stage.